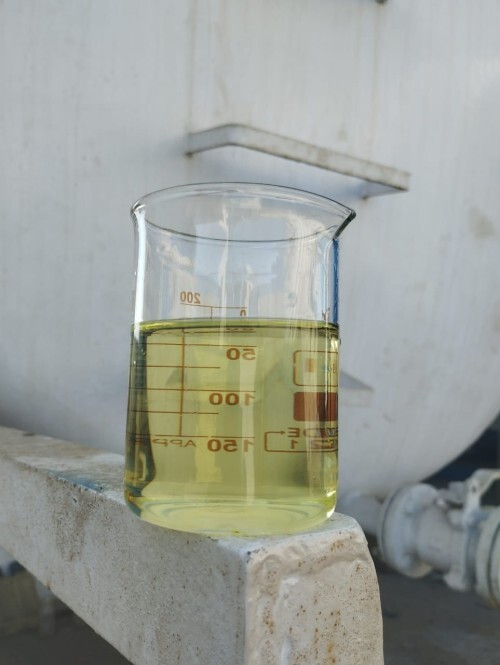

Ferric Chloride Liquid / Iron(III) Chloride (FeCl3)

Ferric Chloride Liquid Iron(III) Chloride Solution ; Ferric Chloride Solution ; Iron Trichloride Solution ; Perchloride of Iron Solution ; FeCl₃ Aqueous Solution. Synonyms Ferric chloride, Iron trichloride, Molysite. Linear Formula: FeCl3 Formula FeCl3 CAS No 7705-08-0 HS Code 28273990 Industries We Serve Water Treatment Chemical Industry Electronics Industry Metallurgy Textile Industry Pulp and Paper Industry Oil and Gas Industry Applications Effluent treatment in Textile, Paper, Refineries, and other Chemical Industries. In Desalination Plants. In Water and Sewage Treatment. In Etching Printed Circuit Boards. In the Manufacture of Several Iron Compounds. In Pharmaceutical Preparations. In Inks and Pigments. In Pickling of Stainless Steel and High Nickel Alloys. In Textile Mordanting. In Petrochemical Industry – ETP Treatment.